Finland’s largest manufacturer and distributor of special metal cutting tools for the metal industry, JR-Tools Oy, is investing in two new CNC grinding machines. The SMP CA7XL and Schneeberger ARIES NGP+ will strengthen the company’s machine capacity for metal cutting tool reconditioning.

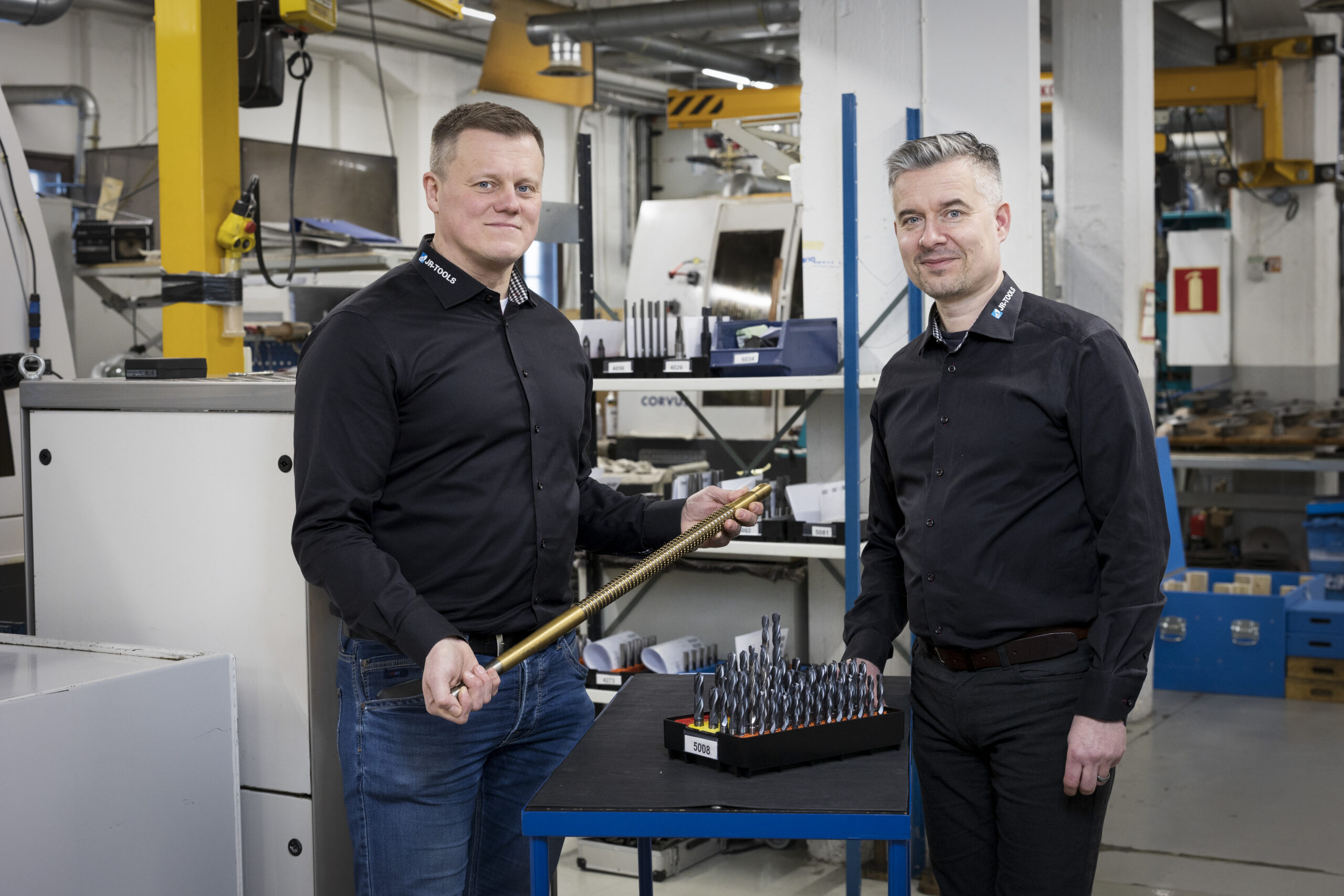

The SMP CA7XL CNC grinding machine is a versatile addition to JR-Tools’ tool resharpening capacity. “This is the first modern 5-axis machine for sharpening long pull broaches in Finland. It is also capable of sharpening gear cutting tools and performing, for example, surface grinding thanks to its detachable magnetic table,” says JR-Tools’ Sales Director Veli-Matti Uusitalo. The company has received a business development grant from the Centre for Economic Development, Transport and the Environment of Central Finland for the acquisition of the machine, meaning the investment is co-funded by the EU.

The Schneeberger ARIES NGP+ CNC grinding machine increases the company’s capacity for carbide drill reconditioning. “We purchased a similar machine a couple of years ago and have been very satisfied with it, so acquiring a second one was an easy decision. It is a fast and compact machine equipped with modern 3D simulation features, and it will be fully occupied from day one,” notes JR-Tools’ CEO Pasi Rönn.

The delivery of the new machines is scheduled to take place this year. JR-Tools’ strategy includes acquiring at least one new machine each year. “These investments enable growth, and overall order development has been positive. Last year, our company’s turnover was around €3.5 million. We are aiming to reach the €4 million mark within the next couple of years,” Uusitalo explains.

Cutting tool maintenance as a sustainability action

JR-Tools offers services for the entire lifecycle of a tool: tools are designed and manufactured according to customer specifications, reconditioned, and finally recycled. By utilising the full life cycle of a tool and recycling it, its carbon footprint is reduced.

“Sustainability is important to us as a company, and this year we have implemented product-specific carbon footprint calculation. When a customer buys a tool from us, we commit to taking care of its reconditioning and recycling as well,” Rönn explains. Proper sharpening and PVD coating of metal cutting tools are also crucial for maximising tool life. “Reconditioning cutting tools is a responsible act, as the carbon footprint of one reconditioning cycle is significantly lower than that of a new tool. From this perspective too, it is easy to justify why we are investing specifically in tool reconditioning,” Rönn continues.

Further information:

CEO Pasi Rönn

+358 (0)50 469 7921

Sales Director Veli-Matti Uusitalo

+358 (0)40 835 8075

JR-Tools Oy is a manufacturer of special cutting tools for the metal industry, operating in Tikkakoski, Jyväskylä, in the historic rifle factory premises. JR-Tools is the largest and most versatile company in its field in Finland, and its machinery enables not only the manufacture of carbide and HSS special tools but also their reconditioning and PVD coating. In addition to its own tool production, the company imports various gear cutting tools.

www.jrtools.fi